IKEA Skadis for organizing your electronics

IKEA Skadis for organizing electronics is a niche community but definitely something you should look at if you want to organize your dev boards

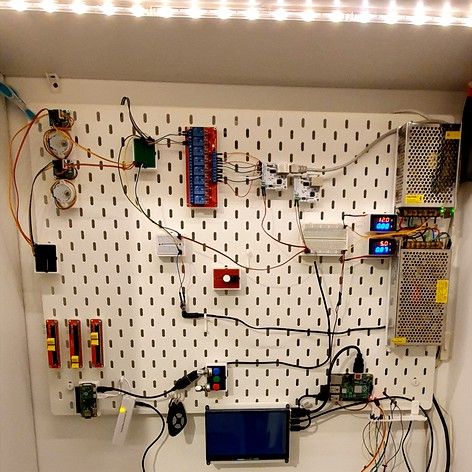

The pegboard with all the electronics is an IKEA Skadis

I have been thinking a lot about organization of hardware, and this has led me down the path of writing this post. A lot of the things in this post are out of firsthand experience, but I have tried to justify my practical learnings using some theory.

Vertical vs horizontal organization

Horizontal surfaces are most comfortable for organizing things that you are actively working on - like this guy working on some metal cutting.

Pegboards as a category of storage are great because they let you organize vertically. This is still not as space efficient as a tool trolley that you might find in an auto garage typically – but that has limitations when it comes to supplying power to the contents of these trolleys. Plus, a trolley like this is going to reduce the amount of walkable space in your workplace, and I equate amount of walking space to ease of thinking*[1] - so that's another downside.

So, in terms of efficient space utilization, we have the following hierarchy - trolley > pegboard > table.But this hierarchy changes when you want to route cables for power and data to the contents of your stuff.

Why use IKEA Skadis?

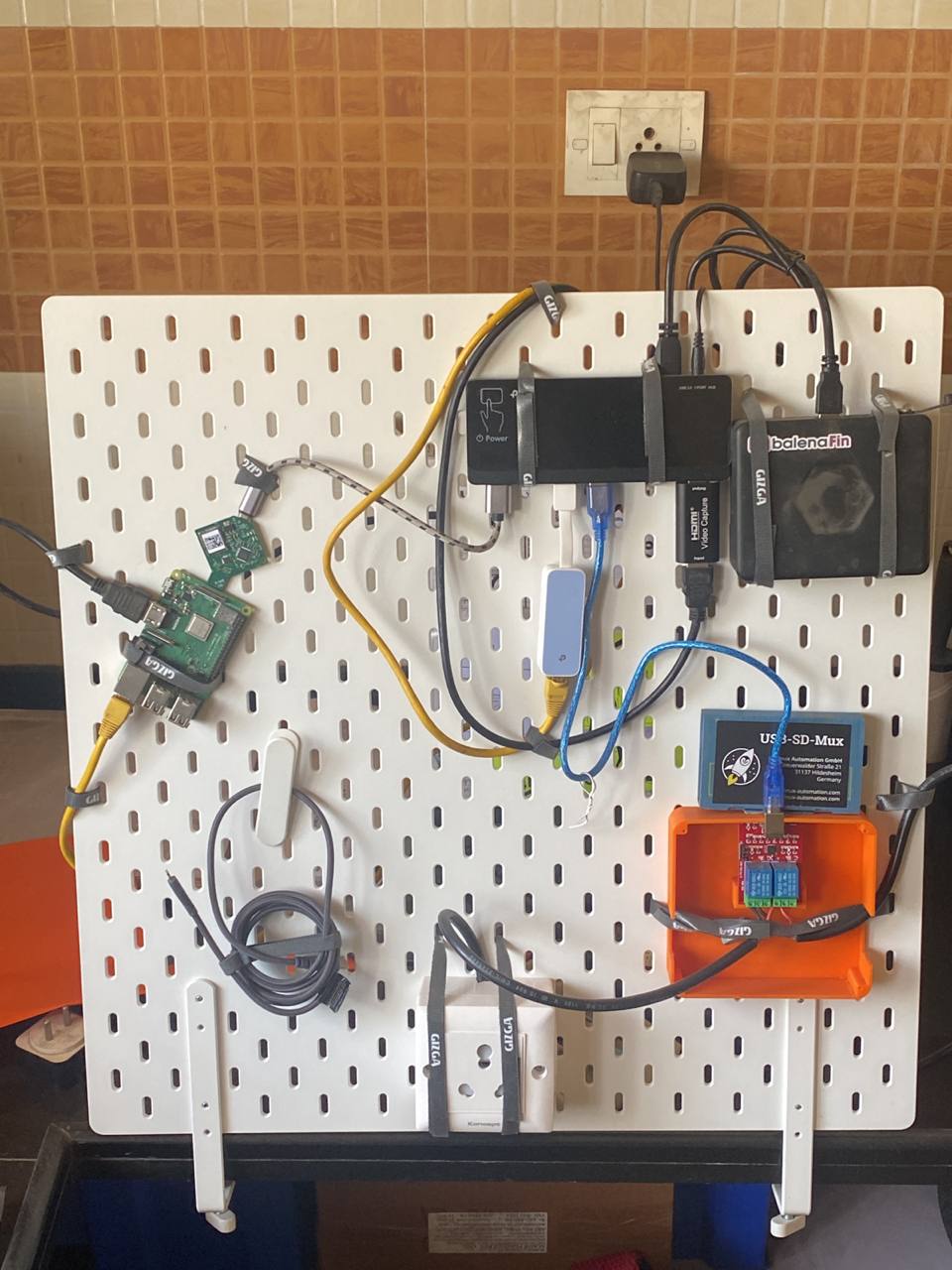

Simple enough reason - people love it and there's a not-enough-spoken-about community of 3D printing hobbyists who use it for their storage needs.

If you head over to printables.com today and search for "IKEA Skadis" you'll find over a thousand designs. These include everything from scissor and screwdriver holders to Raspberry Pi cases that mount on the Swedish pegboard.

I personally use IKEA Skadis pegboards in my house for

- keys

- nerf guns

- devboards

- electronics testing setups

- 3D printing supplies

- screwdriver and plier sets

and more!

Why is it especially good for electronics?

- Space behind the pegboards allows you to route cables. If you notice the above Skadis board, I have you'll see I have some wires going above and then behind the pegboard.

- There are already people designing and sharing models for development boards and power supplies and what not.

- It's cheap. Thanks to IKEA's business model and mass manufacturing in general.

- If you are running testing setups, it helps to easily spot LED patterns/displays when it's right in front of you (as opposed to buzzers or having to look at logs)

Mass manufacturing enables customization

When you drill holes in a wooden plank and use it as pegboard, you are creating something unique. It's not really a standard. You could potentially follow a loosely accepted standard grid - but there's still going to be noticeable differences because of human error.

This raises an interesting point. Skadis is a mass manufactured product. We don't have IKEA artisans building Skadis pegboards and accessories with their bare hands. But if it wasn't mass manufactured and made available in the exact same format around the world, we wouldn't have so many 3D printable designs for it.

So, a mass manufactured product enables a customization at the user level. This thought was a bit counterintuitive for me - because I have always considered mass manufactured and custom products as the opposite ends of the same spectrum.